Sustainability

Responding to Climate Change

Responding to Climate Change

Reducing Greenhouse Gas Emissions

The Nitta Group adheres to the following basic policy in working to reduce greenhouse gas emissions.

Basic Policy for the Reduction of Greenhouse Gas Emissions

As a basic policy for the reduction of greenhouse gas emissions from production processes, the Nitta Group aims to reduce its greenhouse gas emissions by 46% by fiscal 2030 (from our fiscal 2013 level) and to achieve carbon neutrality by fiscal 2050.

Targets for carbon neutrality

-

- The Nitta Group aims to reduce its greenhouse gas emissions by 46% by fiscal 2030 (from the fiscal 2013 level) and to achieve carbon neutrality by fiscal 2050.

- Reduction of greenhouse gas emissions from production sites (plants) in Japan and overseas (Scope 1, 2)

Measures to achieve targets

-

We will thoroughly implement energy-saving efforts, and, for essential energy requirements, introduce green energy and transition to greenhouse gas-free energy, as exemplified by green hydrogen.

- Ongoing energy-saving activities

- Introduction of renewable energy

- Introduction of greenhouse gas-free energy

Energy Conservation

Introduction of environmentally friendly equipment

-

When replacing equipment, the Nitta Group makes sure to adhere to the following in installing equipment with high-efficiency specifications and actively pursues the adoption of equipment eligible for Japan’s Top Runner energy efficiency program.

- Accelerate the transition to LED lighting fixtures.

- When replacing large-scale air conditioning equipment, review the capacity of installed equipment, along with selecting high-efficiency models, and build systems that enable a shift from central air conditioning to zoned air conditioning.

- When replacing power-receiving equipment, select transformer capacities that match current equipment and adopt low-loss, high-efficiency transformers.

- Adopt high-efficiency motors for manufacturing equipment to reduce power load in the standby (preparation) state.

Eliminating steam

-

Our Nara Plant uses steam in production lines and heating fixtures. Steam is much easier to use than some other energy sources, but at the same time it is inefficient and is not suitable for waste heat use. We will actively promote the elimination of steam in equipment that allows manufacturing with heat sources other than steam, and will work to reduce CO2 by reducing energy loss.

Utilizing renewable energy

-

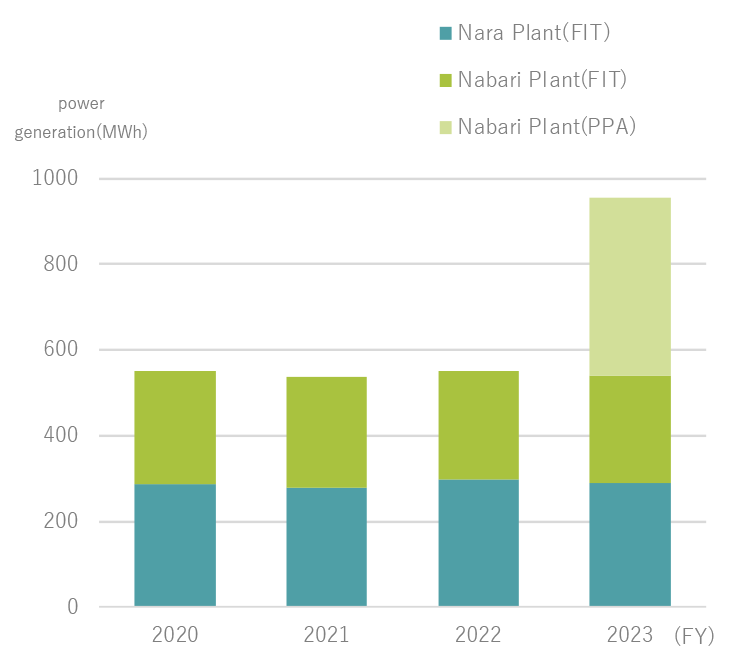

As future initiatives, we will actively introduce sources of renewable energy (especially solar power generation equipment) and will contribute to CO2 reductions in our manufacturing processes by invigorating our energy generation activities. We have already introduced solar power generation equipment at two sites, and are supplying electricity to electric power utilities through the FIT purchasing system. We will actively cooperate with government policies that aim to make renewable energy sources the primary sources of electric power. In fiscal 2023, the Nabari Plant introduced solar power generation equipment through an onsite PPA model*. This facility generates 5.4% of the electricity consumed by the plant.

We plan to begin studies of CO2-free power source adoption as we expand our range of activities to encompass both generation and use, bringing about a large CO2 reduction effect.* A PPA (power purchase agreement) model is a business model in which a PPA operator installs solar power generation facilities on land or rooftops rented from a client and sells the electricity generated there to the client.

Sites with solar panels installed

Both the Nara Plant and Nabari Plant sell electricity to electric power utilities.The Nabari Plant uses the electricity generated by PPA for its own use.

| Item | Nara Plant (FIT) |

Nabari Plant (FIT) |

Nabari Plant (PPA) |

|---|---|---|---|

| Solar power generation capacity (kw) |

275 | 200 | 255 |

| Annual power generation (MWh) |

290 | 251 | 413 |

Nara Plant (FIT)

Nara Plant (FIT)

Nabari Plant (FIT)

Nabari Plant (FIT)

Nabari Plant (PPA)

Nabari Plant (PPA)

Solar power generation